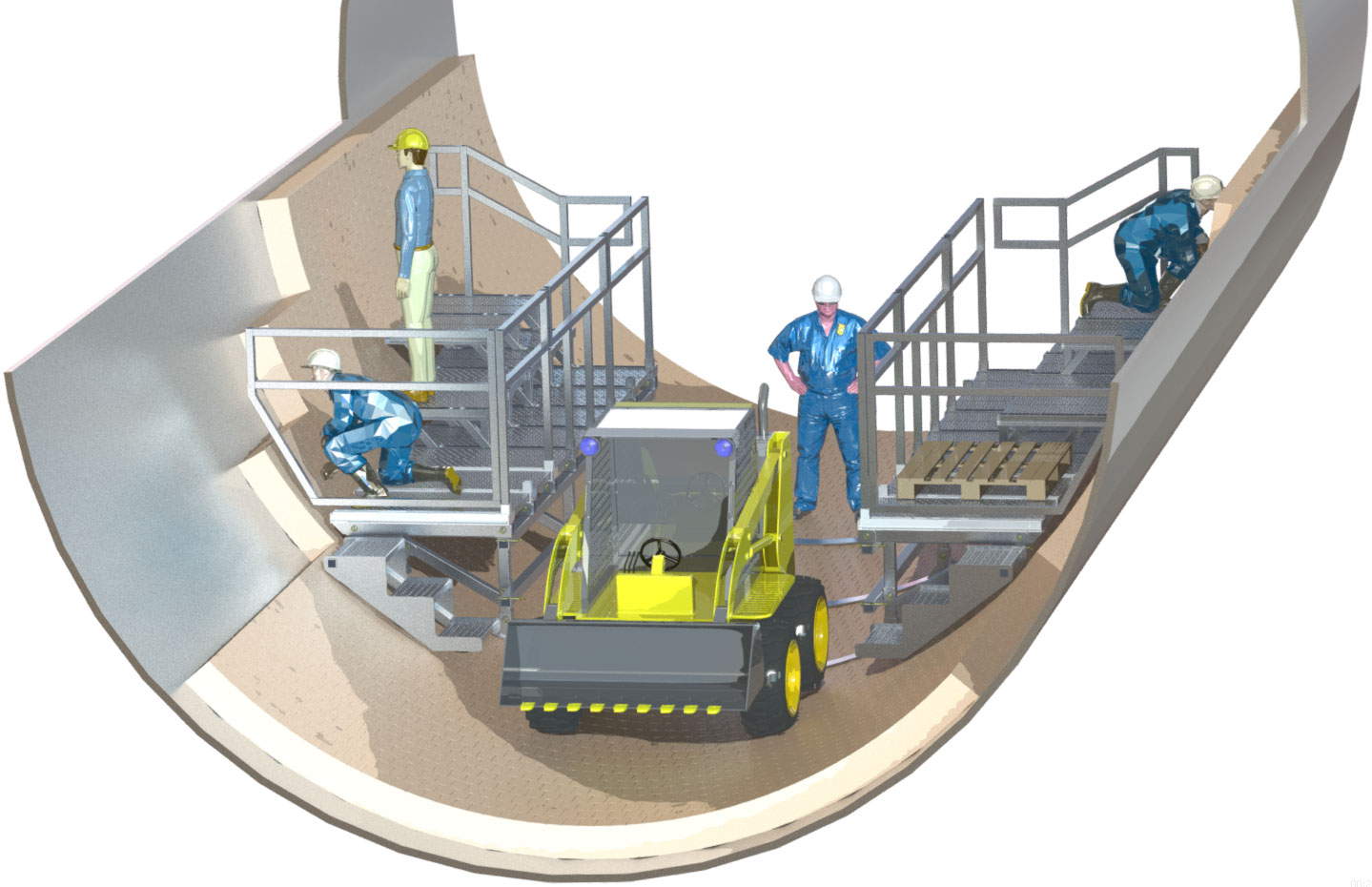

Bricking Solutions, a full solution provider of refractory installation equipment, introduces a bedding cart with a split deck for increased access to brick during refractory brick installation. The Split Bedding Cart features dual decks rather than a single deck in order to provide clearance for a forklift or skid steer. Along with allowing equipment to travel through the kiln to other work areas, the clearance also allows personnel to easily pass, improving efficiency and safety.

“Customers asked for a bedding cart with a split deck for easy access while bricking the bottom of the kiln, and we listened,” said Jeff Mirisola, global sales and service manager at Bricking Solutions. “By giving our customers options between the single deck and the split deck, they can find the right product for the way they work.”

The original bedding cart design greatly increased kiln lining efficiency by giving refractory brick installation crews a flat surface on which to place bricking materials. The use of a bedding cart is much safer than the traditional method of using stacked pallets or springboards for brick storage. The single-deck design gave workers a way to brick the bottom of the kiln in a more stable way. However, the single-deck platform made it impossible to move equipment throughout the kiln. The dual decks of the new Split Bedding Cart provide clearance for equipment and allow room for workers, tools and brick throughout the refractory installation process.

The standard split unit has a minimum width of 1.3 meters (4.25 feet) and fits kilns between 4-7 meters (13.08-23 feet) with sizing customization options. The typical deck features a load capacity of 793 kilograms (1,750 pounds) per side. Curved bottom braces allow forklifts and skid steers to easily drive over and move to the front or back of the cart while inside the kiln. Rubber feet on the sides of the cart protect newly bedded brick.

The Split Bedding Cart makes rebricking the bottom of the kiln to the spring line safer and easier. Workers are able to pass safely between the decks rather than climbing over to gain access to different parts of the kiln. Bricking Solutions recommends using the Split Bedding Cart with a bricking machine, especially in larger kilns where masons cannot reach the spring level while bricking.

Like all Bricking Solutions equipment, the Split Bedding Cart is made with high-quality materials that are rigorously tested for safety. The machine is manufactured with high-strength 6061-T6 aircraft-grade aluminum, which is as strong as steel but only two-thirds the weight. The design is simple to assemble and disassemble with pin connections between parts. Removable fall guards are a standard feature and steps make placing pallets of refractory safer and easier for brick masons. The design included polyurethane double wheels with brakes and an ergonomic step design up to the spring line for increased safety.