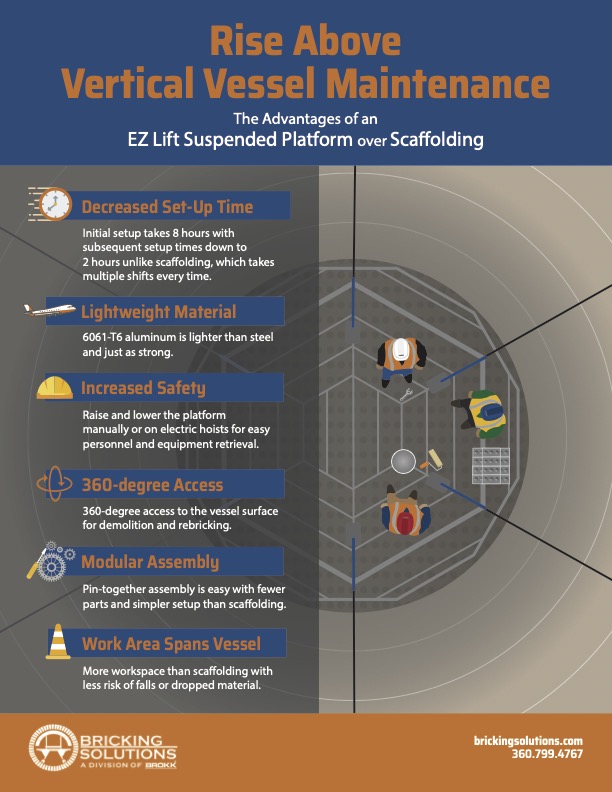

It’s time to upgrade maintenance practices for vertical vessels with Bricking Solutions’ EZ Lift Suspended Platform. Like any routine maintenance, inspecting, removing and replacing refractory in pre-calciners, cyclones, lime kilns, ISAMELT furnaces and other vertical vessels places a costly burden on facilities in terms of downtime and lost productivity. One of the main reasons for this is the traditional solution for accessing vertical surfaces with scaffolding severely limits efficiency and is rife with inherent safety risks.

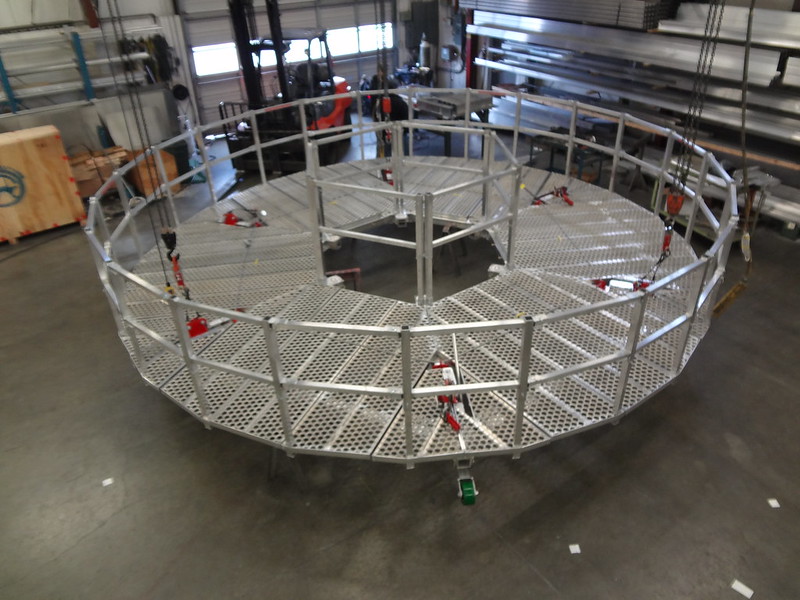

The EZ Lift Suspended Platform, however, offers a safer, more efficient way. These custom-manufactured platforms feature a lightweight, heavy-duty aluminum platform that is assembled inside the vessel and can be raised or lowered using manual or electric hoists for hassle-free maintenance and relining applications. Here’s how the EZ Lift Suspended Platform can boost productivity and safety throughout the maintenance process.

Speedy Setup

The amount of time a scaffolding system takes to set up is its biggest deterrent and the greatest drain on maintenance productivity. Depending on the vessel size and configuration, it can take a crew several shifts or even an entire week to put up the scaffolding.

The EZ Lift Suspended Platform’s modular design and pin-together construction greatly reduce the number of components and tools required for assembly and allow crews to complete setup in as little as two hours.

Modular components manufactured from high-strength 6061-T6 aluminum provide the same strength as steel at a third of the weight. And, because vertical vessels often feature small access points, Bricking Solutions limits the size of modular components. The resulting pieces are easy to maneuver, weighing 18 kilograms (40 pounds) or less, and fit through a 560-millimeter (22-inch) diameter access hole. This provides a lighter, more easily maneuverable solution than scaffolding’s heavy wooden planks and steel pipes, some of which are up to 4.3 meters (14 feet) long.

Pin connections allow for an improved assembly process and enhanced platform strength over welded connections. The pin system also offers greater flexibility while the platform is being raised or lowered along with the ability to easily increase or decrease the diameter, by up to one meter, while the system is installed. Additionally, pin-together joints offer a better solution to maintain safety and stability when dealing with varying speeds from the climbing hoists.

Site Preparation

Suspended platforms require some initial site preparations. They include:

- Ensuring the roof can support the overall load of the platform, hoists, personnel, and materials at a 4:1 safety factor.

- Boring holes into the roof of the vessel for the wire ropes and inserting a threaded pipe in each, so the holes can be capped when the platform is not in use.

- Clearing and leveling the bottom of the vessel or using a dance floor for assembly.

- Ensuring there is an opening of at least 2 feet (0.6 m) in diameter for bringing parts into the vessel.

If the vessel doesn’t have a roof, beams can be used to support the platform. The sidewall just needs to be able to support the load. Bricking Solutions offers telescoping beams that ease installation and ensure proper load rating and safety factor.

These initial steps require some planning ahead; however, in the long run, a suspended platform saves significant time and effort with each use, increases safety for workers and allows a larger working platform to keep all tools and materials within reach. Add the benefits together and it equals a significant ROI advantage over scaffolding.

Room to Move

Even after the platform is assembled, the productivity benefits continue to add up. In terms of surface area, ease of use and access to the work area, the EZ Lift Suspended Platform raises head and shoulders above scaffolding.

With scaffolding, tools and materials need to be hoisted up to working height a little at a time, often by hand, leading to increased risk from climbing up and down as well as potential for repetitive motion injuries. This is a slow process with a heavy physical toll. It also limits productivity by restricting supply lines for materials such as refractory brick, gunning equipment or other necessities.

On the other hand, the EZ Lift Suspended Platform can easily transport up to 2,722 Kilograms (6,000 pounds) up and down, and the open design provides ample space for personnel, tools and materials. This allows several workers to operate comfortably and safely in the same area with everything close at hand for efficient maintenance. The suspended platform provides crews with 360-degree access at a comfortable working height, regardless of the task at hand. All of these safety and ergonomic benefits lead to long-term savings in the form of workman’s compensation claims and insurance premiums.

View from the Top

Making the switch to the EZ Lift Suspended Platform requires some initial planning, but positive returns are almost immediate. Facilities that have made the switch save thousands of dollars with each maintenance cycle, providing a return on investment in as little as one or two uses. The EZ Lift Suspended Platform comes paired with speedy setup, plenty of room to move and a safer work environment that can revolutionize refractory maintenance in vertical vessels.