Bricking Solutions, a full solutions provider in kiln refractory installation equipment, offers Hydraulic and Incline Conveyors to increase maintenance efficiency and reduce worker physical strain. Made from heavy-duty aluminum, these conveyors increase efficiency and safety, while minimizing damage to kilns and refractory materials during routine refractory maintenance.

“Refractory installation is time-consuming but unavoidable,” said Heather Harding, Bricking Solutions managing director.

“We strive to make routine installation safer, easier and faster for our clients by designing equipment that ensures crews can work effectively no matter what they’re up against.”

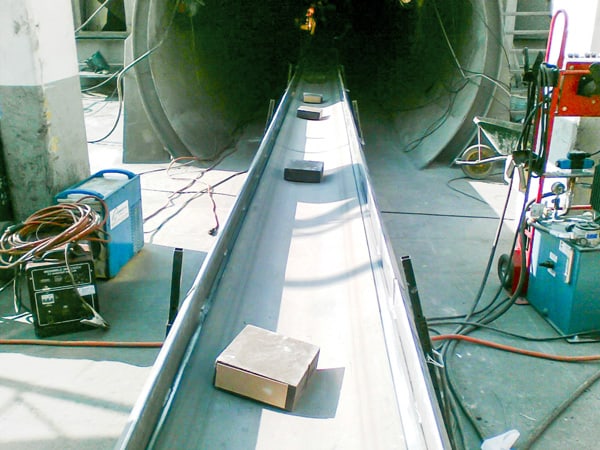

The company’s conveyors are made from the same 6061-T6 aircraft aluminum that gives their bricking machines and suspended platforms industry-leading strength with significantly less weight. The sections weigh just 16-19 kilograms (35-42 pounds), making transportation and installation easy for a small crew. This, coupled with a modular design, allows for quick setup in as little as one to two hours, depending on the length of the conveyor and site conditions. Hydraulic Conveyors are also equipped with easy-to-assemble 3-meter (10-foot) belt sections that form a continuous surface up to 76.2 meters (250 feet) long.

Using a 5-horsepower hydraulic drive, the Hydraulic Conveyor moves up to 907 kilograms (2,000 pounds) in either direction at a rate of up to 45 meters per minute (150 feet per minute). This allows crews to remove material twice as fast as manual methods and a two-person crew can bring a full pallet of brick into the kiln in less than 10 minutes. With a roller conveyor, it would take a crew of five up to three hours to move the same number of bricks. Three width options — 30.5, 50.8, 76.2 centimeters (12, 20 and 30 inches) — and the flexibility provided by the modular construction allow Bricking Solution engineers to custom design conveyors to fit any site requirements. These conveyors can be set up on the ground, spring boards or elevated on adjustable legs for safe operation, regardless of terrain. As installation moves further into a kiln, Hydraulic Conveyors are ideal for safely and efficiently transporting bricks and refractory from the staging site to the bricking machine.

The Incline Conveyor relies on an electric motor to transfer brick and refractory from the kiln floor to the bricking machine with minimal effort. The unit pairs with any size bricking machine and is ideal for difficult-to-access sites where forklifts are unable to operate. Operating height is between 1.80 meters (5 foot, 11 inches) with a 20-degree incline and 3.49 meters (11 foot, 5 inches) with a 40-degree incline. Wheels are attached to the base section for easily adjusting slope. The 1 horsepower (746 kilowatt) motor, requiring a 110/220-volt (50/60 hertz) connection, is capable of moving 15-20 bricks per minute.

All Bricking Solution conveyors come with standard safety features that protect crews and worksites. On the Hydraulic Conveyor, an emergency stop button halts the conveyor belt within three seconds. An optional pull cord emergency stop can also be added along the full length of the conveyor for added safety. The Incline Conveyor is equipped with an emergency shut off switch at both ends. An open center design minimizes buildup under the belt and idler rollers reduce friction over connection joints to extend belt life and decrease the risk of malfunctions and safety hazards. The use of a conveyor system also protects workers from unnecessary body strain and reduces damage to kiln and refractory materials during transportation.

“Safety is our top priority,” Harding said. “We want to make sure that everyone goes home uninjured at the end of the day, and our conveyors are a perfect example of that commitment. Whether that’s back strain from carrying heavy refractory or protection from falling debris, we do our best to make sure workers are exposed to as little risk as possible.”

Contact us here to learn more!