Brick management has a significant impact on overall refractory installation efficiency. Up kiln or down, having bricks delivered in a way that’s comfortable for you and your crew increases productivity and safety.

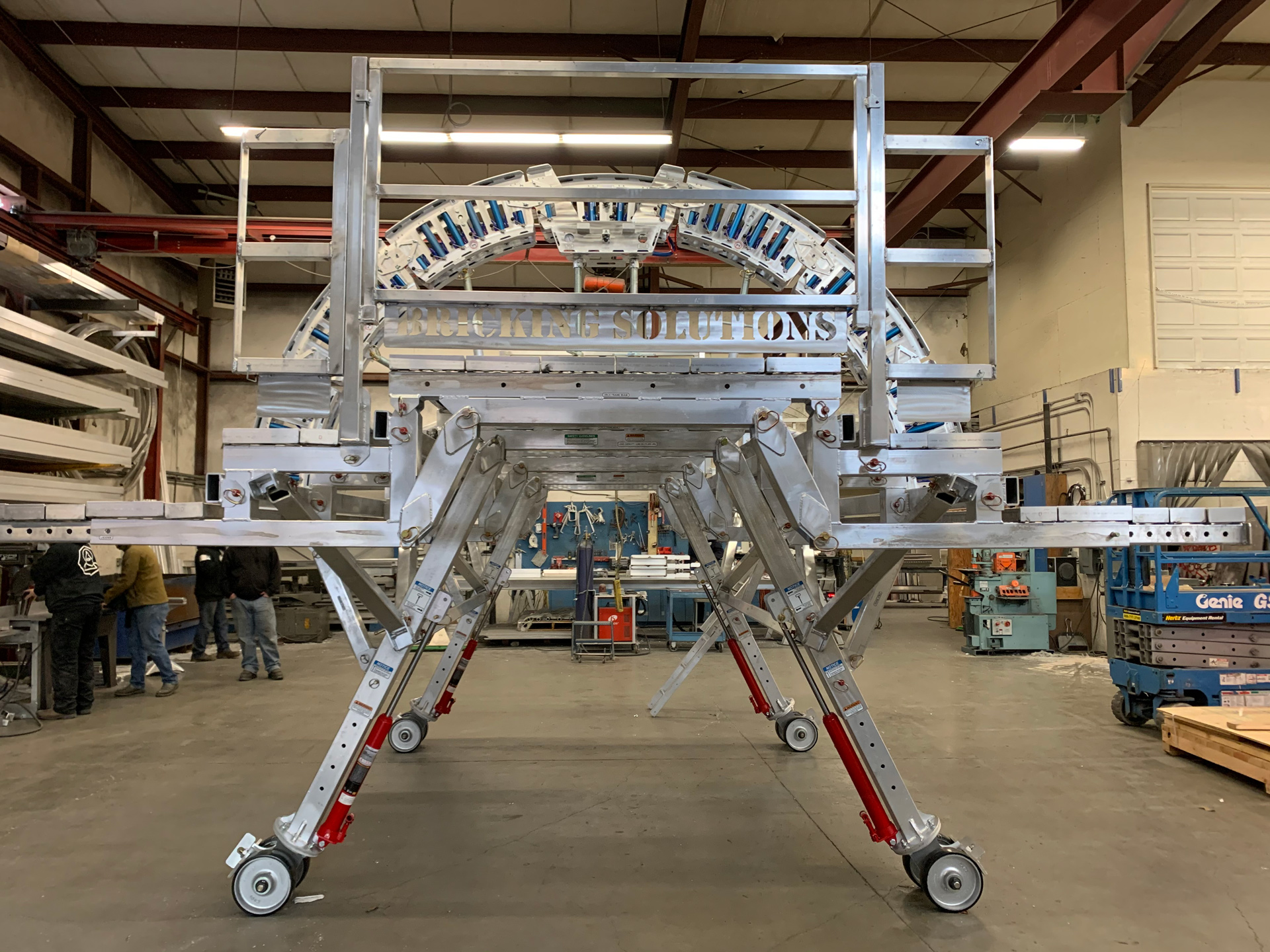

To increase brick management options, we recently released a new Stair-Stepped Bricking Machine. The new model retains the key benefits of our EZ Flexx50 Bricking Machine — which offers the lightest weight and highest load capacity on the market — but with a few tweaks to allow customers to tailor their refractory installation process for maximum comfort and efficiency.

Here’s how the new bricking machine helps you step up refractory installation efficiency.

Extra Clearance for More Brick Management Options

The new stair-stepped design provides enough clearance to drive support equipment, such as skid steers or forklifts, underneath the machine. This allows crews to easily deposit refractory brick for the bedding crew and bricking machine on the keying side. This style of brick management minimizes brick handling and reduces the need for additional equipment, such as conveyors, to deliver brick. This, in turn, improves productivity and reduces brick damage and loss associated with the constant material handling.

The 4- to 5-meter (13.1- to 16.4-foot) Stair-Stepped Bricking Machine offers approximately 213 centimeters (84 inches) of clearance. 5- to 6-meter (16.4- to 19.7- foot) models provide approximately 264 centimeters (104 inches). Actual clearance is dependent on machine configuration and kiln size.

But don’t worry, the stair-step design doesn’t hinder usable deck space. There’s still plenty of room for all your tools, personnel and materials.

Industry-Leading Deck Size and Capacity

Like our EZ Flexx50, the Stair-Stepped Bricking Machine still offers the largest decks in the industry — both in terms of size and capacity. The standard unit has a 4.3-meter (14-foot) long deck and can hold as much as 3,992 kilograms (8,800 pounds). The largest model’s platform is 5.2 meters (17.1 feet) long — larger than any competitive machine — and can hold three pallets of brick totaling 6,000 kilograms (13,200 pounds).

The key is high-strength 6061-T6 aircraft-grade aluminum, which is as strong as steel but only two-thirds the weight. With our lightweight, modular design and pin-together construction, the Stair-Step Bricking Machine can be set up in just 60 to 90 minutes, compared to 6 to 8 hours for many competitive models.

Ergonomic Bricking

The Stair-Stepped Bricking Machine also offers improved ergonomics. By positioning workers and bricks on the stair steps, crews can stage brick at midlevel, minimizing lifting and bending. Additionally, we’re the only manufacturer to include an ergonomic cut-away section in the front arch to allow keying access to close out a ring. Double arches support two rings at once for efficient installation, allowing masons to start installing the next ring while the previous is keyed out. These features allow an experienced crew to install 1 meter (3.3 feet) of brick per hour, compared to roughly .6 meters (2 feet) per hour with other techniques.

Efficient Refractory Installation – One Step at a Time

The Stair-Stepped Bricking Machine gives you more flexibility for brick management that fits your process while still providing the fast set up, ample deck space and easy keying that Bricking Solutions’ bricking machines are known for.

Ready to step up your refractory installation experience?