BRICKING SOLUTIONS, Fig. 1: Ergonomic Cut-out section in front arch – Allows key mason room and keying access to close out row.

Load Capacity: Standard 4000kg (8000 lb): 2 pallets of brick plus workers and tools.

Optional 6000kg (13228 lb): 3 pallets of brick plus workers and tools.

Optional small kiln 2722kg (6000 lb):1 pallet of brick plus workers and tools.

COMPETITION, Fig. 1: Arch sections at the top are the same as everywhere else.

Load Capacity: Standard 2722 kg (6000 lb).

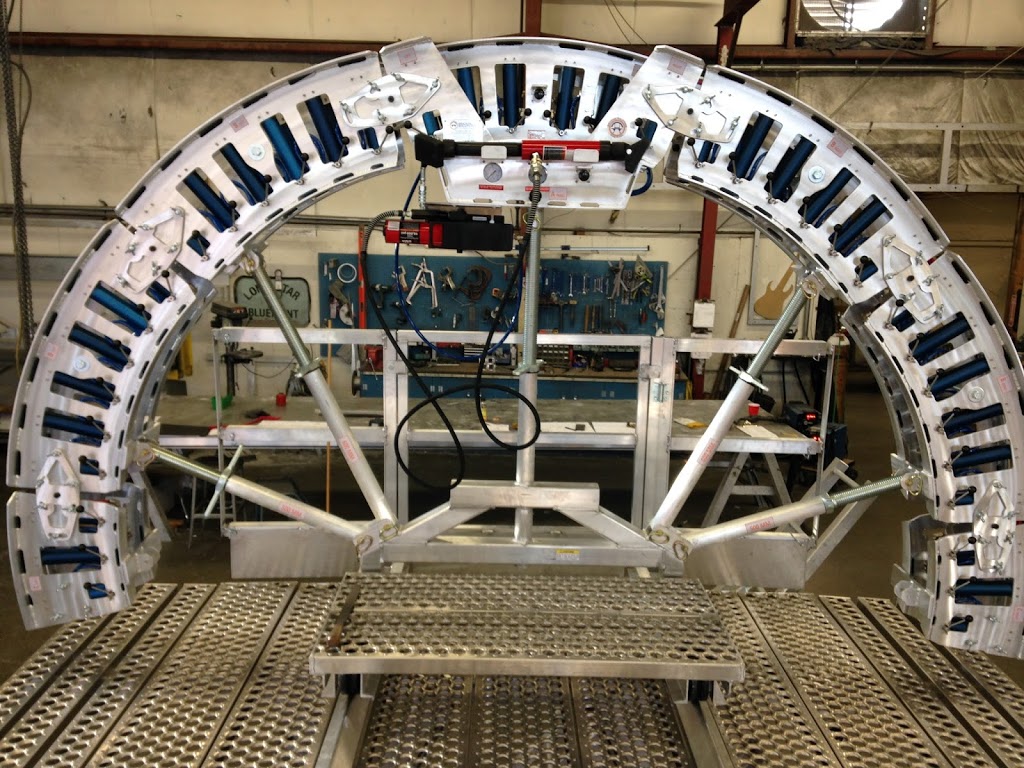

BRICKING SOLUTIONS, Fig. 2: Aluminum dual arch with engineered cut-outs – lightweight & secured on the arch stabilizer post. Adjustable screw jacks & hinge connections – Adjustments with no tools.

Arch Adjustment: Adjustable screw jacks & hinge connections – Adjustments with no tool.

COMPETITION, Fig. 2: Add or remove cylinder segments, estimated 400 kg heavier, must be installed with aid of a “grip hoist” & special fixture.

Arch Adjustment: Add or remove cylinder segments, estimated 400 kg heavier, must be installed with aid of a “grip hoist” & special fixture.

BRICKING SOLUTIONS, Fig. 3: Ergonomically designed stair step that moves along center rails on work deck.

Machine Weight: 1400 kg (3087 lb) 5M machine: as strong as steel but 1/3 of the weight.

995 kg (2193 lb) 3M machine

COMPETITION, Fig. 3: Drag along jump scaffold or not supplied. Manually picked up and moved or dragged with arch movement.

BRICKING SOLUTIONS, Fig. 4: Dual Master Valve for single or simultaneously activation. Easy accessible cylinders for quick repairs.

Assembly: Symmetrical part design with pin connections for fast and easy assembly. Under 2 hour assembly time with minimally experienced crew.

COMPETITION, Fig. 4: One valve, cylinders enclosed in panels making change out difficult and time consuming.

Assembly: 4 to 6 hours – longer if the arch segments are not pre-assembled.