Equipment Safety Evaluations

Our objective is to ensure Bricking Solutions’ customers achieve the optimum usefulness of their Refractory Installation Equipment at all times. We will note all components that need to be replaced or repaired and advise you on what safety upgrades are available for your machine. We will also train plant personnel and/or contractors on hand in general maintenance, safety and storage procedures.

Commissioning

Bricking Solutions not only stands behind everything we manufacturer, but we also stand right next to you as a support system to insure your refractory installation equipment will give you the best performance each and every outage. The beginning of that support system starts with our New Machine Commissioning. We will go over the assembly, maintenance and storage requirements of your new equipment.

Yearly Maintenance Schedules

You can opt to have your machine put on a schedule and have it maintained for you. We can visit your facility 1 or 2 times per year and maintain the equipment. Regular maintenance keeps the costs down. This also ensures your machine is ready for any outage but that it is being recertified by the original manufacturer of the equipment. Safety is our priority as well.

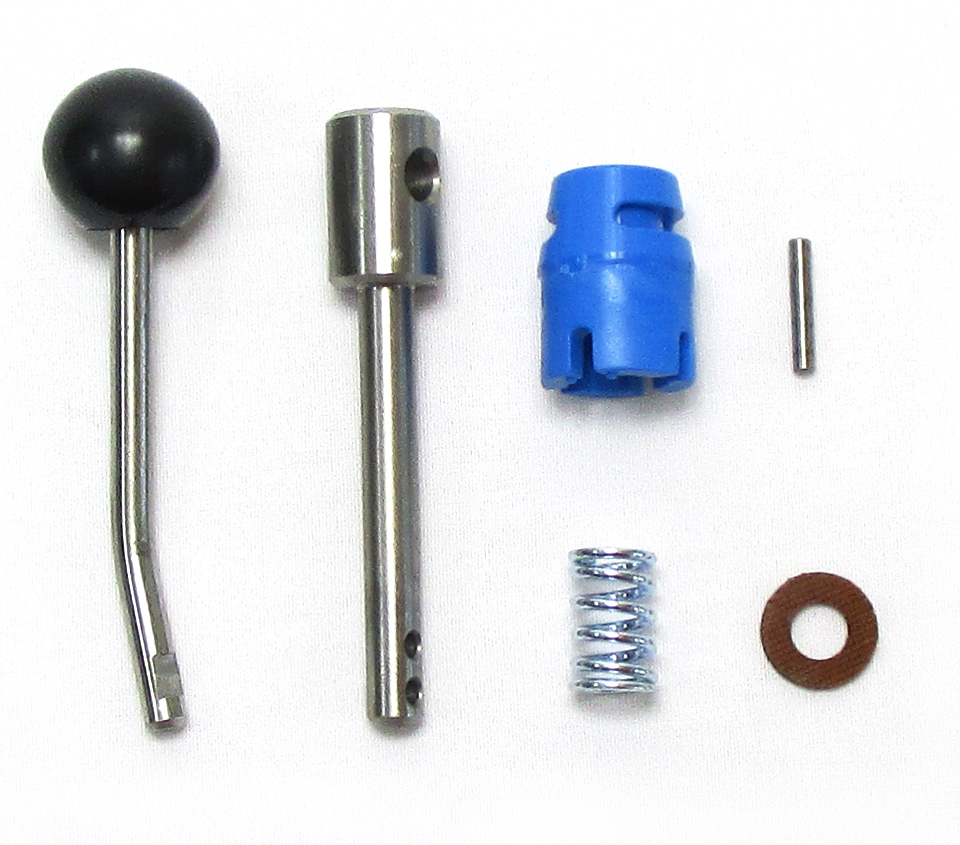

Parts

Let us assist you in maintaining your stock of inventory. We will go over what is absolutely necessary to have on hand and what is not. Also:

- What has a shelf life and what is obsolete.

- Dating your rebuilds and incoming parts.

- Keeping your yearly maintenance cost low and tracking changes.

- Keeping maintenance logs.

It might sound simple enough but you would be surprised how many people don’t do this and end up behind the eight ball during an outage or end up scrambling two days before they use the machine.

Design or Part Changes

Lubricator Filters – 01-2015 (PDF)

New 40mm Cylinders vs 30mm – 07-2012 (PDF)

New Cylinder Shafts – 04-2012 (PDF)

Contact Jeff Mirisola to learn more or to schedule your evaluation:

360-799-4767 or EMAIL